When designing high-performance electronic devices, choosing the right PCB type is crucial. While traditional PCBs serve well in many applications, Custom Metal Core PCBs offer advanced benefits in thermal management and durability. But what exactly makes a Custom Metal Core PCB different? Let’s explore the key distinctions and why industries increasingly prefer metal core solutions.

What Is a Custom Metal Core PCB?

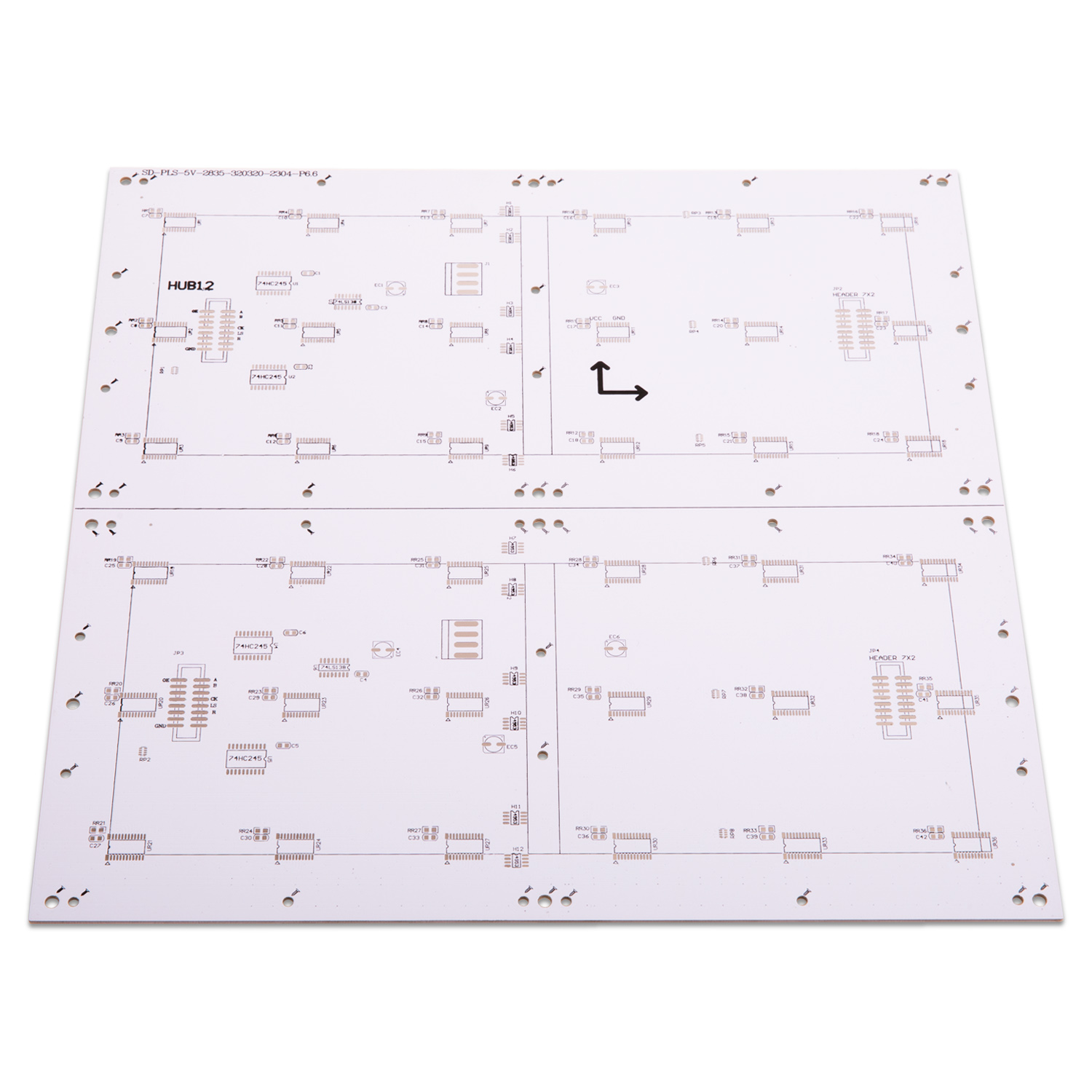

A Custom Metal Core PCB (MCPCB) is a specialized printed circuit board that integrates a metal base, usually aluminum or copper, to improve heat dissipation. Unlike traditional PCBs that rely on standard FR4 materials, a high-performance Custom Metal Core PCB efficiently transfers heat away from critical components, preventing overheating and extending product lifespan.

Key Components of a Custom Metal Core PCB

Metal Substrate – Provides structural support and superior thermal conductivity.

Dielectric Layer – Acts as an insulating barrier between the circuit layer and metal core.

Circuit Layer – Contains the copper traces that conduct electrical signals.

Key Differences Between Custom Metal Core PCBs and Traditional PCBs

Thermal Management

One of the most significant advantages of Custom Metal Core PCBs is their ability to handle high temperatures. Traditional PCBs, typically made from FR4 materials, have limited thermal conductivity. In contrast, a high-efficiency Custom Metal Core PCB transfers heat rapidly, making it ideal for LED lighting, automotive electronics, and power systems.

Durability and Mechanical Strength

Traditional PCBs, while cost-effective, are more susceptible to mechanical stress and temperature variations. Durable Custom Metal Core PCBs, on the other hand, provide superior mechanical strength and resistance to warping, making them ideal for demanding environments.

Electrical Performance

A low-loss Custom Metal Core PCB offers enhanced electrical performance, reducing signal interference and maintaining consistent power delivery. This makes it a preferred choice for high-frequency applications.

Application Scope

While traditional PCBs work well in consumer electronics, custom-designed Metal Core PCBs are widely used in:

LED lighting systems

Power conversion equipment

Industrial automation

Why Choose Our Custom Metal Core PCB Solutions?

At Hongmy, we specialize in manufacturing Custom Metal Core PCBs tailored to meet industry-specific requirements. Whether you need a high-thermal conductivity Custom Metal Core PCB for power applications or a precision-engineered Custom Metal Core PCB for advanced electronics, we provide fully customized solutions with:

Advanced thermal management technology to enhance performance.

High-quality metal substrates for increased durability.

Custom design support to meet specific industry needs.

When it comes to choosing between traditional PCBs and Custom Metal Core PCBs, the decision depends on performance requirements. If your applications demand superior heat dissipation, durability, and electrical efficiency, Custom Metal Core PCBs are the right choice.