In today’s advanced technology landscape, custom Rigid-Flex PCB solutions are essential for improving the quality and efficiency of complex devices. Combining the flexibility of flexible circuits with the strength of rigid boards, these PCBs offer numerous advantages across industries such as aerospace, medical, and consumer electronics. As device designs become more sophisticated, the demand for custom Rigid-Flex PCB continues to grow, offering superior reliability and enhanced performance.

Space Efficiency in Compact Designs

One of the primary benefits of custom Rigid-Flex PCB is the ability to save space. By integrating rigid and flexible sections, these boards eliminate the need for bulky connectors and additional wiring. This space-saving feature is crucial for small, lightweight devices such as medical implants and portable electronics.

Moreover, fewer interconnections reduce potential failure points, increasing product longevity. Custom Rigid-Flex PCB allow for more complex and compact designs without compromising functionality.

Improved Mechanical Durability

Complex devices often operate in challenging environments where mechanical stress, vibrations, and temperature changes can affect performance. Custom Rigid-Flex PCB are engineered to withstand these conditions. Their flexible sections allow movement without damaging the board, while rigid parts provide structural support.

This combination enhances durability, making custom Rigid-Flex PCB ideal for industries requiring high-performance, reliable components. Devices in aerospace, automotive, and industrial sectors benefit from these durable solutions.

Enhanced Electrical Performance

Custom Rigid-Flex PCB offer better electrical performance by reducing the need for connectors and cables. This streamlined structure minimizes signal loss and electromagnetic interference (EMI), ensuring reliable data transmission.

For high-speed applications, such as telecommunications and advanced medical devices, maintaining signal integrity is vital. Custom Rigid-Flex PCB support faster and cleaner data flow, optimizing overall system performance.

Simplified Assembly and Cost Savings

Although the design process for custom Rigid-Flex PCB may be complex, their assembly is more efficient. By reducing the number of connectors and cables, manufacturers save time and labor during production. This streamlined approach also lowers material costs and reduces the risk of assembly errors.

Additionally, custom Rigid-Flex PCB minimize maintenance and repair costs due to their robust construction. This cost-effective advantage makes them an attractive solution for high-volume production.

Design Flexibility for Custom Applications

The versatility of custom Rigid-Flex PCB allows engineers to create unique designs tailored to specific applications. These boards can be shaped and layered to fit unusual spaces, offering innovative solutions for modern electronic devices.

From wearable technology to industrial machinery, custom Rigid-Flex PCB provide the flexibility needed for advanced product designs. Their adaptable nature supports a wide range of applications, making them ideal for custom and specialized devices.

Increased Reliability in Dynamic Environments

Devices exposed to constant motion or extreme conditions require components that can handle physical stress. Custom Rigid-Flex PCB are designed to perform reliably in such environments. The flexibility allows the board to move without breaking, while the rigid sections offer stability.

Industries like robotics and military electronics rely on custom Rigid-Flex PCB for their ability to maintain functionality under continuous movement and harsh environmental conditions.

Why Choose Our Custom Rigid-Flex PCB?

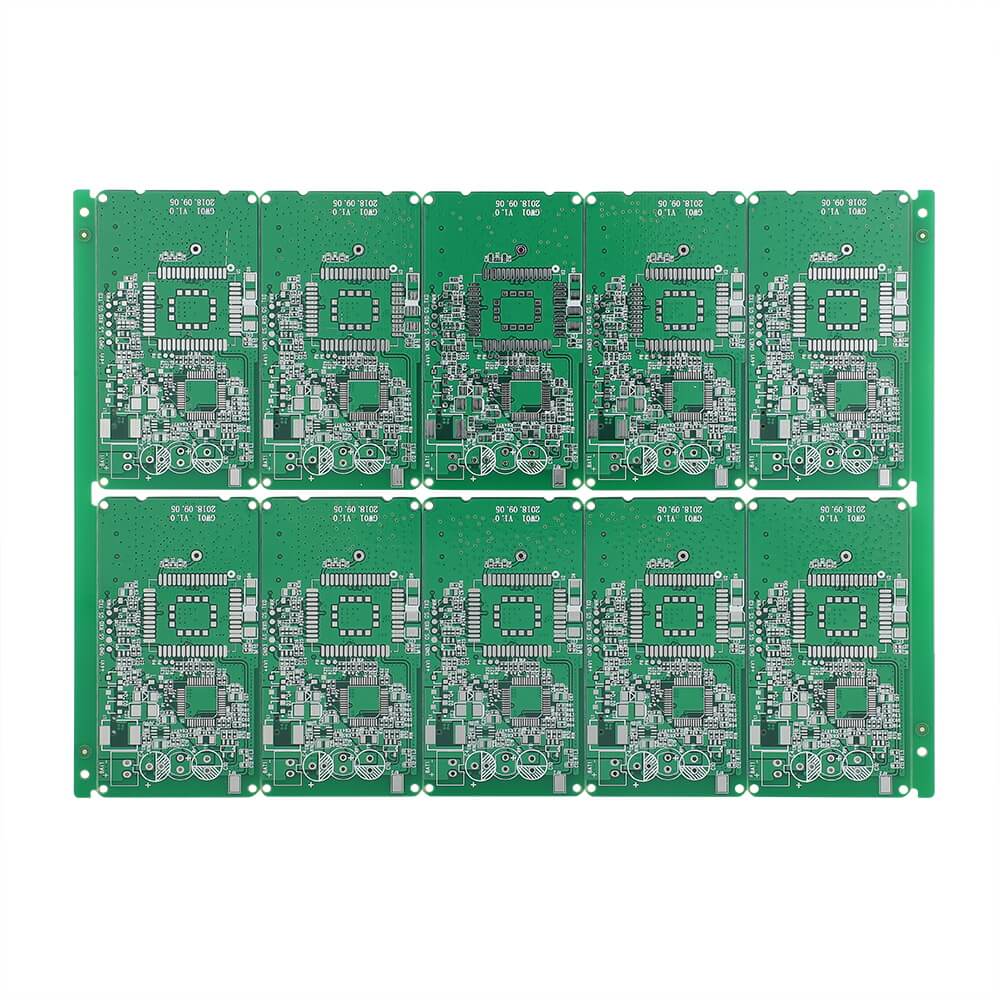

At Hongmy, we specialize in manufacturing custom Rigid-Flex PCB tailored to your unique requirements. Our advanced technology and experienced team ensure the highest quality and performance.

We offer a range of custom Rigid-Flex PCB options, including multi-layer Rigid-Flex PCB, thin Rigid-Flex PCB, and high-precision Rigid-Flex PCB. Whether your application requires complex configurations or specialized materials, our solutions deliver superior results.

Our commitment to quality and innovation ensures that your products benefit from the latest advancements in custom Rigid-Flex PCB manufacturing.