Rigid-flex PCBs (Printed Circuit Boards) combine the best features of both rigid and flexible PCBs, offering durability, flexibility, and compact designs. This unique technology is revolutionizing the electronics industry by providing enhanced functionality, reliability, and space-saving solutions for various applications. In this blog, we will explore what rigid-flex PCBs are, their advantages, and the key considerations when designing and manufacturing them. If you're looking for high-quality rigid-flex PCBs, Hongmy PCB is your trusted manufacturer.

What are Rigid-Flex PCBs?

Rigid-flex PCBs are a hybrid of rigid and flexible printed circuit boards, designed to meet the increasing demand for smaller, more complex electronic devices. As the name suggests, rigid-flex PCBs combine the rigidity of traditional PCBs and the flexibility of flexible PCBs, resulting in a versatile solution ideal for various applications. These PCBs feature rigid sections where mechanical strength and support are needed and flexible sections that allow bending and folding for more compact designs.

Typically, rigid-flex PCBs are used in applications that require durability and the ability to bend, such as in mobile devices, medical devices, automotive systems, aerospace, and wearable technology.

Advantages of Rigid-Flex PCBs

1. Space Efficiency

Rigid-flex PCBs offer excellent space-saving opportunities by eliminating the need for connectors or cables. The flexibility of the PCB allows designers to arrange the board in three-dimensional configurations, optimizing the available space within electronic devices. This compactness is especially important for small electronic products, like wearables, where saving space is crucial.

2. Enhanced Durability

One of the key benefits of rigid-flex PCBs is their durability. These boards are resistant to vibrations, impacts, and thermal stress, making them suitable for harsh environments. The flexible sections help reduce the risk of mechanical failure due to bending or vibration, while the rigid sections ensure the board maintains its shape and functionality.

3. Improved Performance

With fewer connectors and interconnections, rigid-flex PCBs reduce the chances of signal interference and power loss, ensuring more reliable and high-performance circuits. These PCBs also offer higher density compared to traditional rigid PCBs, enabling greater functionality in smaller spaces.

4. Reduced Assembly Costs

By combining flexible and rigid PCBs into a single board, manufacturers can reduce assembly time and costs. The elimination of connectors, cables, and multiple interconnecting parts streamlines the production process, resulting in more cost-effective solutions.

5. Greater Design Flexibility

Rigid-flex PCBs provide excellent design flexibility, allowing engineers to create intricate circuit patterns that fit the specific needs of their products. Designers can utilize the flexible sections to conform to complex geometries, enabling creative and innovative designs without compromising the overall integrity of the circuit.

Applications of Rigid-Flex PCBs

1. Consumer Electronics

Rigid-flex PCBs are increasingly used in consumer electronics, including smartphones, tablets, laptops, and wearables. They help reduce the size and weight of devices while maintaining excellent performance. Their durability ensures that these devices can withstand daily use, ensuring a longer lifespan.

2. Medical Devices

In the medical field, rigid-flex PCBs are used in devices such as hearing aids, pacemakers, and other portable medical equipment. These PCBs are ideal for medical devices because they offer high reliability, compactness, and resistance to environmental stresses, such as moisture and temperature changes.

3. Automotive Industry

The automotive sector also benefits from rigid-flex PCBs, especially in advanced driver-assistance systems (ADAS), in-vehicle infotainment systems, and electric vehicle (EV) components. These PCBs withstand the vibrations, temperature extremes, and physical stresses that are typical in automotive environments.

4. Aerospace and Military Applications

In aerospace and military systems, rigid-flex PCBs are used in high-performance applications such as navigation systems, communication devices, and avionics. Their ability to function reliably in extreme conditions, including high altitudes, extreme temperatures, and vibrations, makes them invaluable in these industries.

5. Wearable Technology

With the increasing demand for compact, lightweight, and durable wearables, rigid-flex PCBs are ideal for applications such as smartwatches, fitness trackers, and health monitors. Their flexibility allows them to fit into curved or irregular shapes, making them perfect for wearable electronics.

Considerations When Designing and Manufacturing Rigid-Flex PCBs

While rigid-flex PCBs offer many advantages, there are some important considerations during their design and manufacturing:

1. Material Selection

Choosing the right materials for both the flexible and rigid sections is crucial. The flexible section typically uses polyimide or similar flexible materials, while the rigid sections use standard PCB materials such as FR4. The compatibility of these materials ensures the integrity and longevity of the PCB.

2. Design Complexity

Designing a rigid-flex PCB requires advanced knowledge and expertise. The complex nature of these PCBs demands precise design and manufacturing processes. Working with a professional PCB manufacturer, like Hongmy PCB, ensures that the design and manufacturing are done to the highest standards.

3. Thermal Management

Managing heat dissipation in rigid-flex PCBs is critical, especially in high-power applications. Proper design strategies, such as incorporating heat sinks or using materials with good thermal conductivity, can help prevent overheating and ensure the long-term reliability of the PCB.

4. Manufacturing Cost

Although rigid-flex PCBs offer cost-saving advantages in assembly, the manufacturing process itself is more complex and requires specialized equipment. As a result, the initial production costs may be higher than traditional rigid or flexible PCBs. However, the long-term benefits often outweigh these costs, especially in terms of durability and performance.

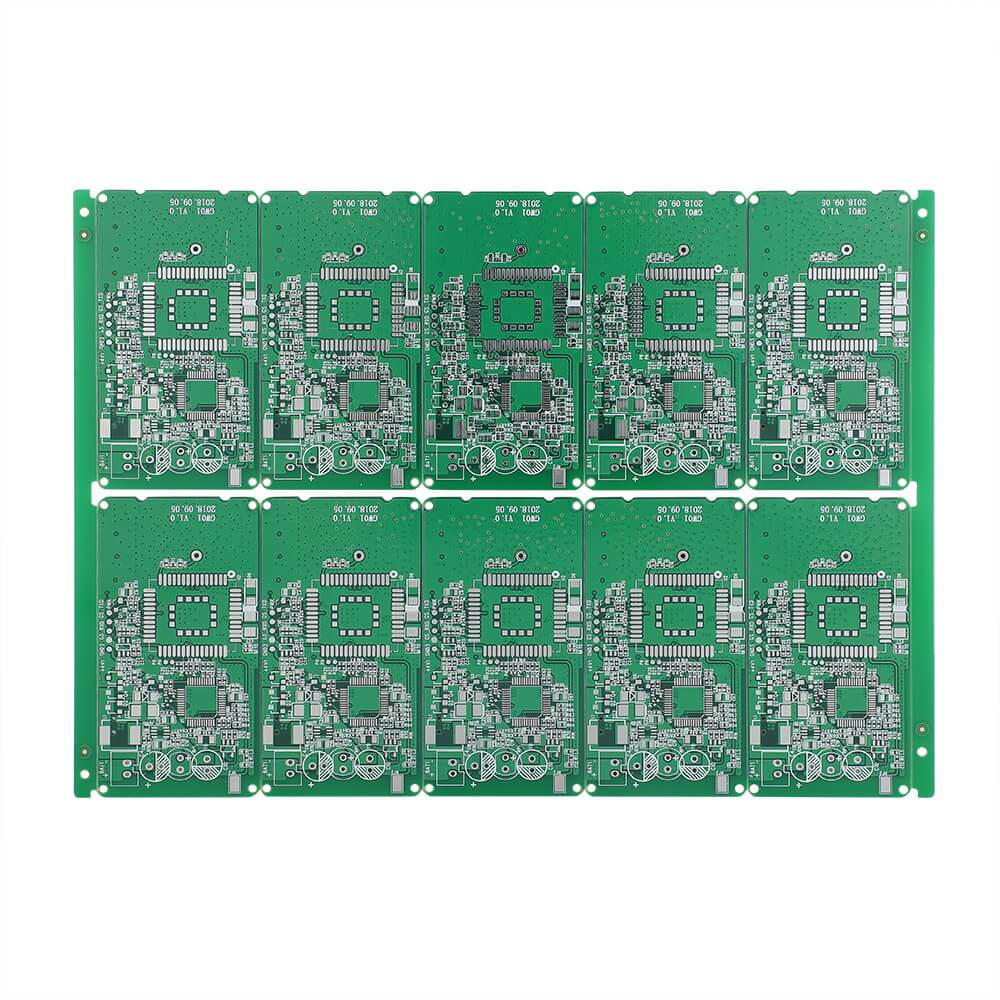

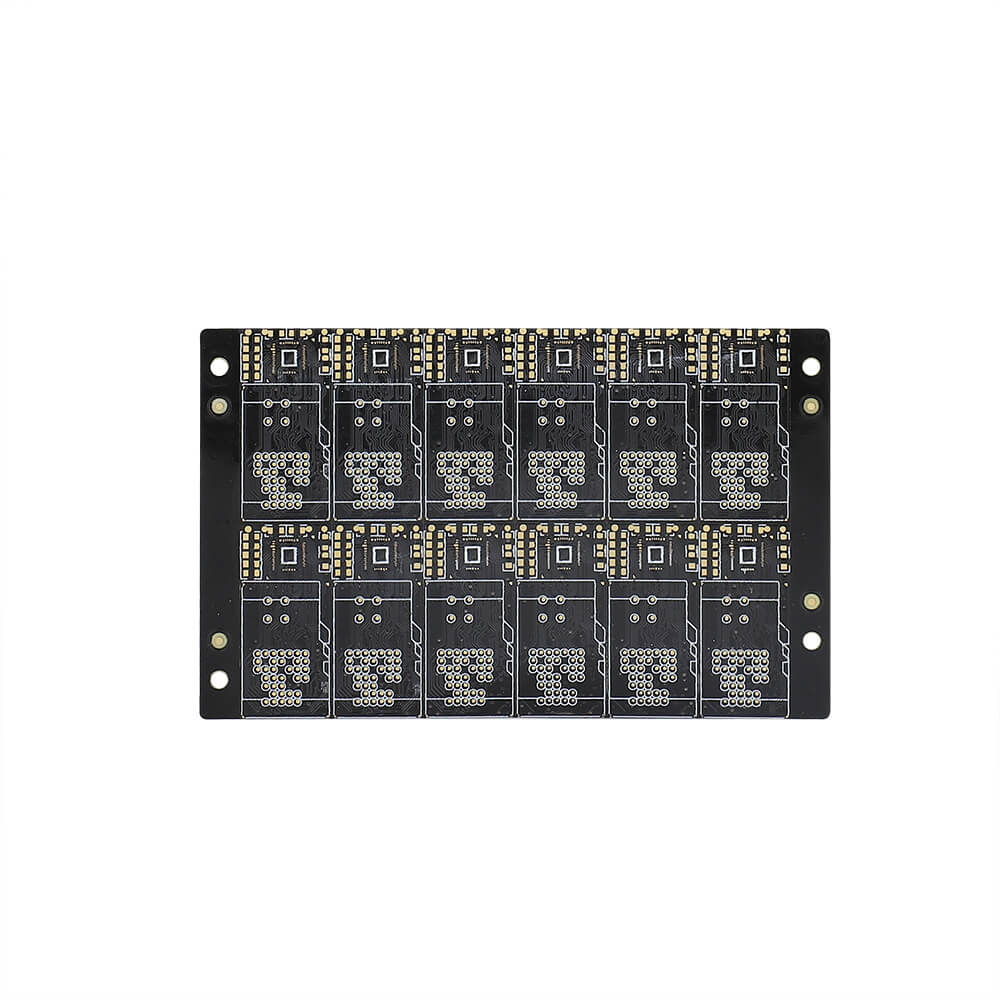

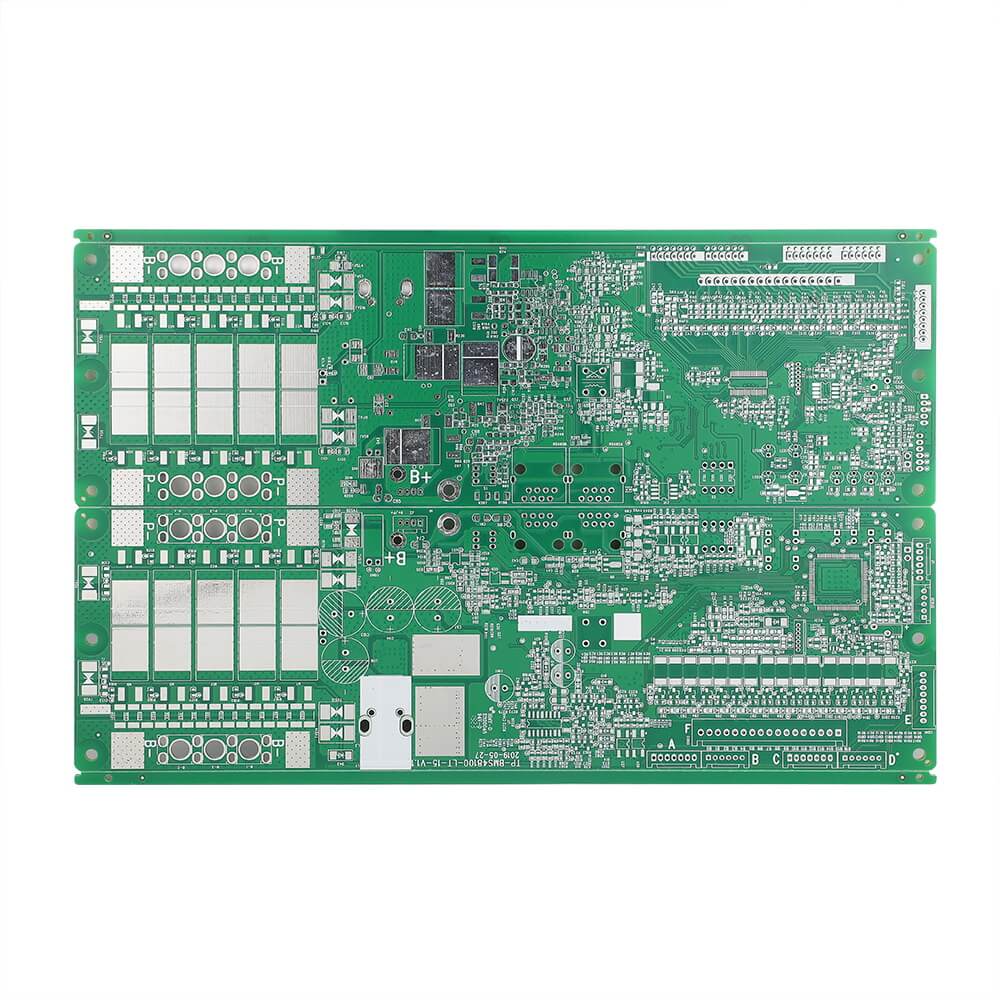

Why Choose Hongmy PCB for Rigid-Flex PCB Manufacturing?

At Hongmy PCB, we specialize in designing and manufacturing high-quality rigid-flex PCBs tailored to meet the needs of various industries. Our team of experts ensures that every rigid-flex PCB we produce adheres to the highest standards of quality, durability, and performance. Whether you are looking for solutions for consumer electronics, medical devices, or automotive systems, we provide custom-designed PCBs that deliver reliable and cost-effective results.

We work with the latest technology and offer comprehensive support throughout the design, prototyping, and production stages. With Hongmy PCB, you can trust that your rigid-flex PCBs will meet your specific requirements and stand up to the demands of your application.

Conclusion

Rigid-flex PCBs represent the future of electronic design, providing an innovative solution for compact, durable, and high-performance circuits. Their versatility and numerous advantages make them an excellent choice for a wide range of applications, from consumer electronics to medical and automotive systems. At Hongmy PCB, we are committed to delivering custom rigid-flex PCBs that meet your needs, ensuring the reliability and performance of your products.

If you're looking for high-quality rigid-flex PCBs, contact Hongmy PCB today and discover how we can help bring your designs to life.