Custom Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, powering everything from smartphones to industrial machinery. Whether you're a seasoned electronics engineer or a DIY enthusiast, understanding how to design and order your own PCB is crucial for creating efficient and reliable products. In this guide, we'll walk you through the key aspects of designing and ordering custom PCBs, with a focus on our manufacturing expertise at Hongmy PCB. We’ll also highlight the importance of industry benchmarks, such as JLCPCB, and how their services have set high standards in PCB production.

Why Design Custom PCBs?

1.Tailored for Specific Applications:

Custom PCBs allow you to design boards that meet the exact requirements of your application. From form factor to connectivity, every detail can be customized to suit your needs.

2.Enhanced Performance:

Custom designs can optimize the performance of your product by integrating components in the most efficient layout. This results in improved signal integrity and reduced electrical noise.

3.Cost Efficiency in Mass Production:

While prototyping a custom PCB can be more expensive than using off-the-shelf solutions, it can lead to significant cost savings in large-scale production. This is particularly true when you optimize for minimal component usage and assembly complexity.

Key Steps to Designing a Custom PCB

1. Define Your Requirements

Start by outlining the functionality and specifications for your PCB. This includes understanding the following:

Form factor: The size and shape of the PCB.

Component layout: Where each component will be placed.

Electrical requirements: Voltage, current, and signal type.

Thermal management: Heat dissipation considerations for components that generate heat.

2. Choose the Right Materials

PCBs are typically made from materials like FR4 (a common fiberglass material), but the choice of substrate depends on the application. For high-frequency or high-performance designs, materials like Rogers or Teflon might be required.

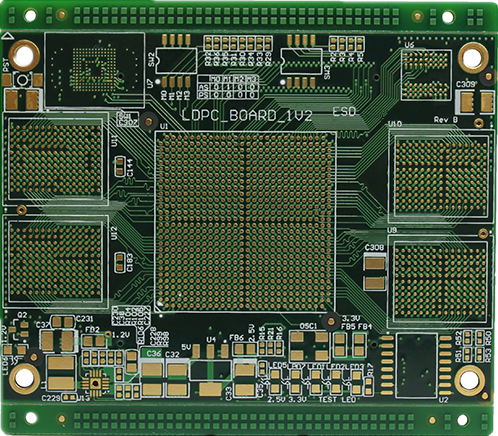

3. Design the PCB Layout

Using PCB design software (such as Altium Designer, Eagle, or KiCad), start designing the circuit board. Ensure proper spacing between traces, create a clear ground plane, and consider signal routing for optimal performance. During this phase, you will also define:

Via types (through-hole, blind, or buried vias).

Trace width and spacing.

Component footprints.

4. Simulate the Design

Before moving forward with manufacturing, use circuit simulation tools to check for potential errors. Tools like SPICE simulations help you verify signal integrity and electrical performance.

5. Generate Gerber Files

Once the design is finalized, generate the Gerber files, which provide the detailed specifications for the PCB fabricator. These files include layer information, drill files, and bill of materials (BOM).

Ordering Your Custom PCB

Once your design is ready, the next step is selecting a PCB manufacturer. Here are the factors to consider when ordering your custom PCB:

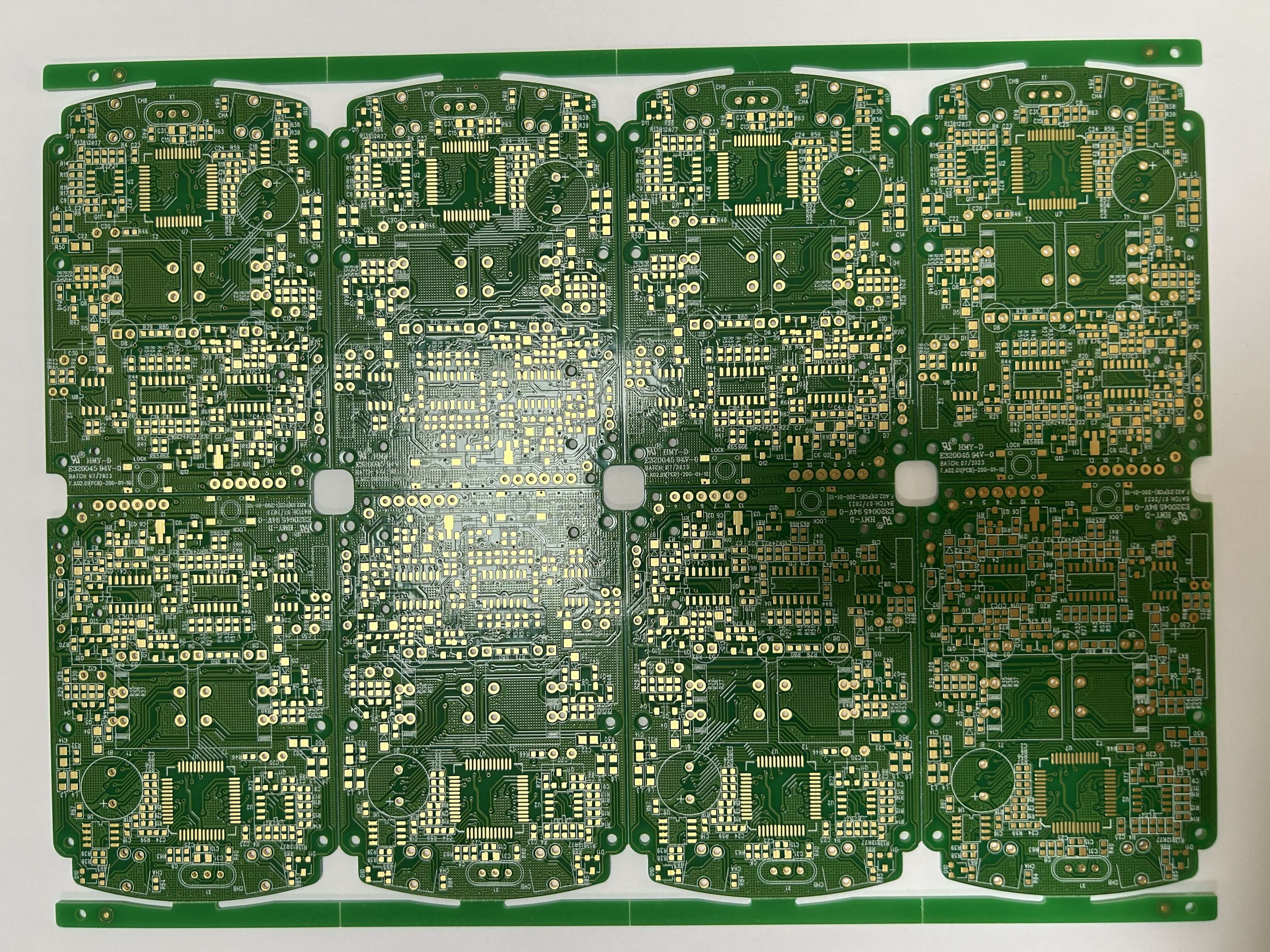

1. Manufacturing Capabilities

Different PCB manufacturers offer varying capabilities, such as the number of layers, minimum trace width, and materials available. It’s important to choose a manufacturer who can meet the complexity and quality standards required by your design.

2. Turnaround Time

Consider the time frame for both prototyping and mass production. Many manufacturers, like Hongmy PCB, offer fast prototyping services, enabling you to test your design before committing to a larger batch.

3. Quality Control

Quality assurance is essential to ensure your PCB functions as intended. Reputable manufacturers, such as JLCPCB, are known for their strict quality control measures, including automated optical inspection (AOI), electrical testing, and environmental testing.

4. Pricing

Pricing varies depending on the complexity of the PCB and the quantity ordered. Custom PCBs with unique specifications may cost more upfront but can lead to long-term savings by improving product performance. Hongmy PCB offers competitive pricing with transparent cost breakdowns, helping you make informed decisions.

5. Support and Communication

Choose a manufacturer that provides excellent customer support. From design revisions to production updates, having clear communication channels can save time and reduce errors.

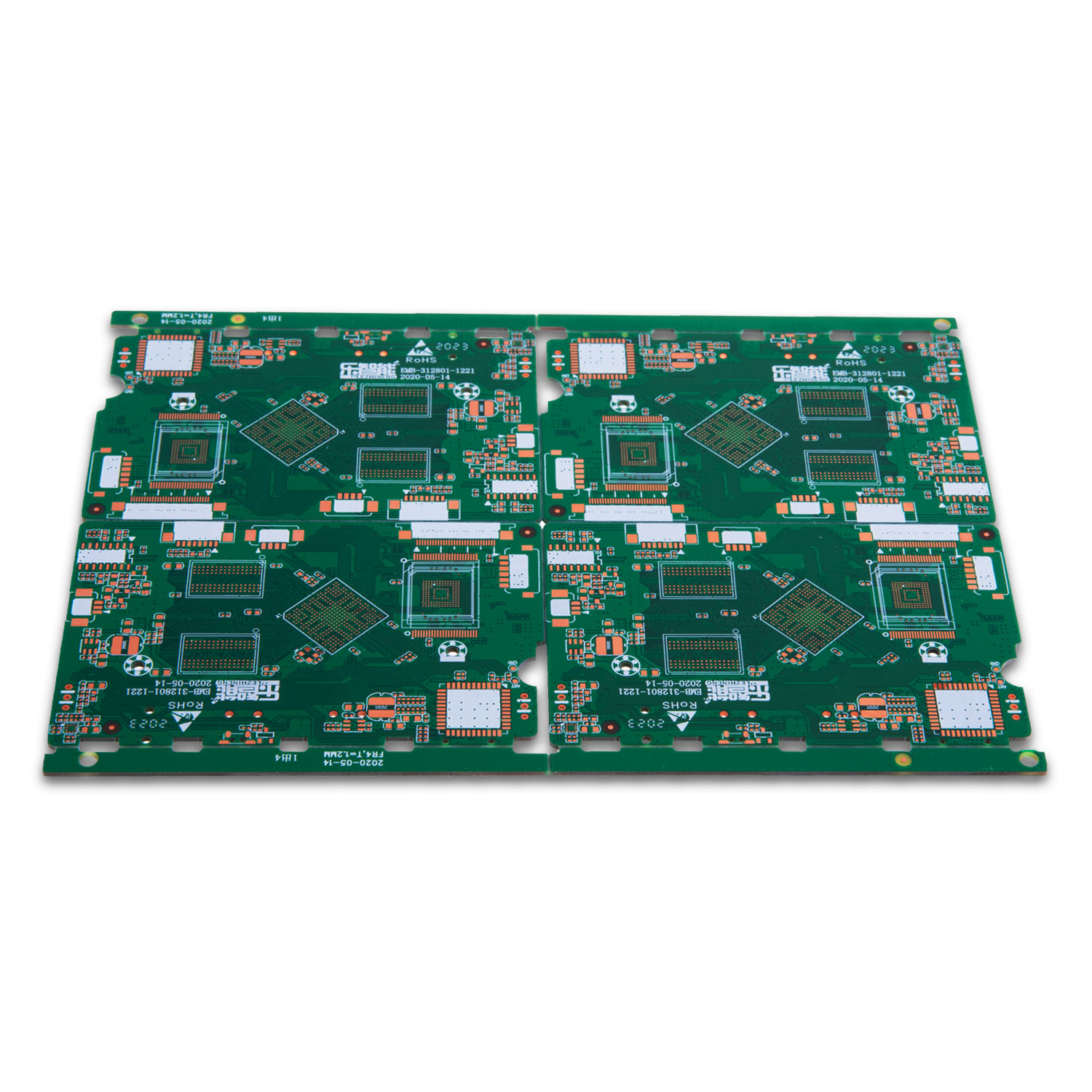

Why Hongmy PCB is Your Trusted Partner

At Hongmy PCB, we specialize in producing high-quality custom PCBs for a wide range of applications. With years of experience in the industry, we are equipped to handle everything from single-layer prototypes to multi-layer HDI boards. Our state-of-the-art manufacturing facilities and commitment to precision make us a reliable choice for your custom PCB needs.

We understand the importance of reliable support and efficient communication. Our team works closely with you at every stage of the process, ensuring your design is optimized for manufacturability and meets the required standards.

Learning from Industry Leaders: JLCPCB

When discussing custom PCB manufacturers, JLCPCB is often considered a benchmark in the industry. Their success lies in their ability to provide high-quality PCBs at competitive prices with fast turnaround times. They are known for offering reliable prototyping services and have earned a strong reputation for delivering high-volume production with impressive consistency.

At Hongmy PCB, we keep a close eye on industry leaders like JLCPCB to ensure that our own processes, quality standards, and customer service remain on par with the best in the industry.

Conclusion

Designing and ordering your custom PCB is an exciting yet intricate process that requires careful attention to detail and collaboration with a capable manufacturer. By following the steps outlined in this guide, you can create a high-performance PCB that meets your product’s specific requirements.

Whether you're prototyping or preparing for large-scale production, Hongmy PCB offers expert manufacturing services and quality assurance to help bring your ideas to life. While JLCPCB sets high standards for the industry, Hongmy PCB is equally committed to delivering excellence and helping you succeed with your custom PCB projects.

If you're ready to get started, contact us today, and let’s turn your design into reality.