In the rapidly evolving world of electronics, the demand for compact, high-performance devices is ever-increasing. High Density Interconnect (HDI) PCBs have emerged as a critical component in meeting these demands, offering unparalleled precision and performance. This article explores the features, benefits, and applications of HDI PCBs in advanced electronics.

What are HDI PCBs?

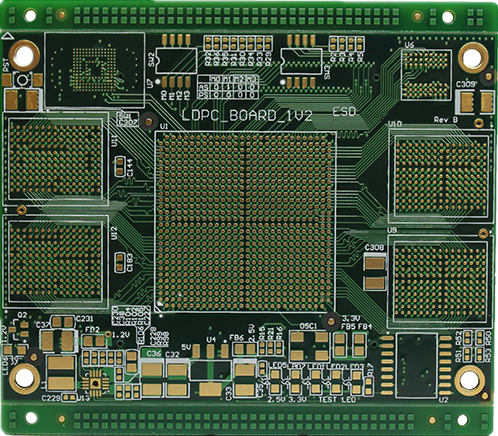

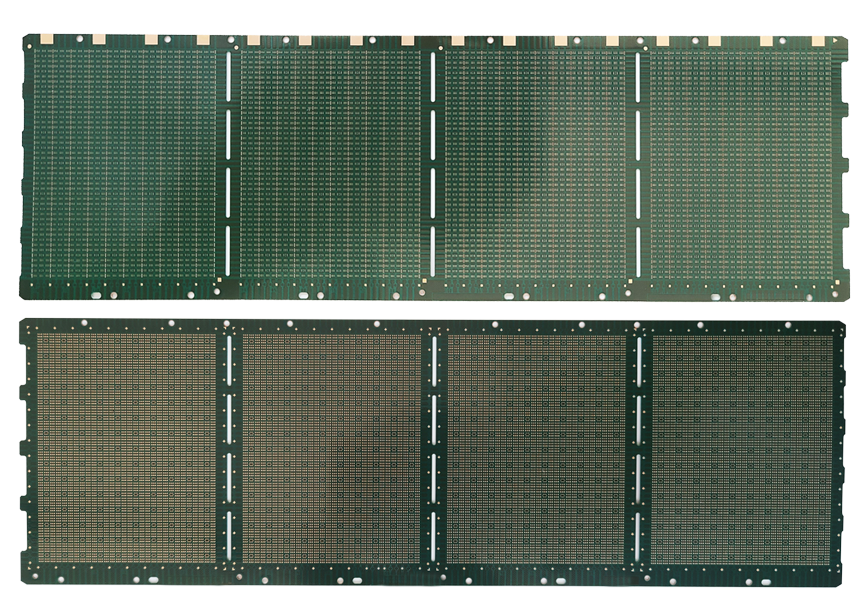

HDI PCBs, or High Density Interconnect Printed Circuit Boards, are a type of circuit board that uses a higher wiring density per unit area than traditional PCBs. They incorporate finer lines and spaces, smaller vias, and capture pads, allowing for more components to be placed on both sides of the raw PCB. HDI PCBs typically use microvias, blind vias, and buried vias and are known for their high reliability and enhanced electrical performance.

Features of HDI PCBs

1.Microvias: These are very small vias that connect different layers of the PCB. They are typically laser-drilled and provide a reliable and efficient way to interconnect layers without occupying much space.

2.Blind and Buried Vias: Unlike through-hole vias that pass through the entire board, blind vias connect the outer layer to an inner layer, while buried vias connect two inner layers without reaching the outer surface. This allows for more complex designs and better signal integrity.

3.Higher Layer Count: HDI PCBs can have multiple layers, allowing for more complex circuitry and functionality in a smaller footprint.

4.Thin Lines and Spaces: HDI PCBs have finer lines and spaces, which increases the routing density and reduces the overall size of the PCB.

5.High Component Density: The ability to place components on both sides of the board, combined with the use of microvias, allows for a higher component density, enabling more functionality in a smaller space.

Benefits of HDI PCBs

1.Miniaturization: HDI technology allows for the creation of smaller and more compact devices, which is crucial in the development of modern electronics such as smartphones, tablets, and wearable devices.

2.Improved Performance: The high interconnect density and shorter signal paths result in lower signal loss and better electrical performance, making HDI PCBs ideal for high-frequency and high-speed applications.

3.Increased Reliability: The use of advanced manufacturing techniques and materials enhances the reliability and durability of HDI PCBs, reducing the likelihood of failures.

4.Cost-Effective: Despite the higher initial manufacturing costs, HDI PCBs can be more cost-effective in the long run due to their ability to integrate more functions into a single board, reducing the need for multiple PCBs and interconnections.

Applications of HDI PCBs

HDI PCBs are widely used in various advanced electronic applications, including:

1.Consumer Electronics: Smartphones, tablets, and wearable devices utilize HDI PCBs to achieve their compact sizes and high functionalities.

2.Automotive Industry: HDI PCBs are used in advanced driver-assistance systems (ADAS), infotainment systems, and other electronic control units (ECUs) to enhance vehicle performance and safety.

3.Medical Devices: Compact and reliable HDI PCBs are critical in medical devices such as imaging systems, diagnostic equipment, and portable medical devices.

4.Aerospace and Defense: The high reliability and performance of HDI PCBs make them suitable for aerospace and defense applications, where space constraints and stringent performance requirements are prevalent.

5.Telecommunications: HDI PCBs are used in network equipment, including routers, switches, and servers, to support high-speed data transmission and processing.

Conclusion

The evolution of electronic devices toward smaller, more powerful, and more reliable systems has driven the adoption of HDI PCBs. Their high precision, performance, and ability to support advanced functionality make them indispensable in modern electronics. As technology continues to advance, the role of HDI PCBs in the development of innovative electronic solutions will only become more significant, shaping the future of various industries.