When it comes to choosing the right printed circuit board (PCB) for your project, understanding the differences between various types is essential. Two popular PCB options are FR4 PCBs and metal core aluminum base PCBs. Both are widely used, but each has its own set of benefits depending on the application. In this article, we’ll break down the key differences between FR4 PCBs and metal core aluminum base PCBs, highlighting the best use cases for each, especially focusing on Hongmy Circuits' expertise in these products.

1. Material Composition

FR4 PCB: The most common PCB type, FR4, is made of a fiberglass-reinforced epoxy laminate that offers electrical insulation and mechanical strength. Its non-conductive properties make it a popular choice for a wide variety of low-heat applications.

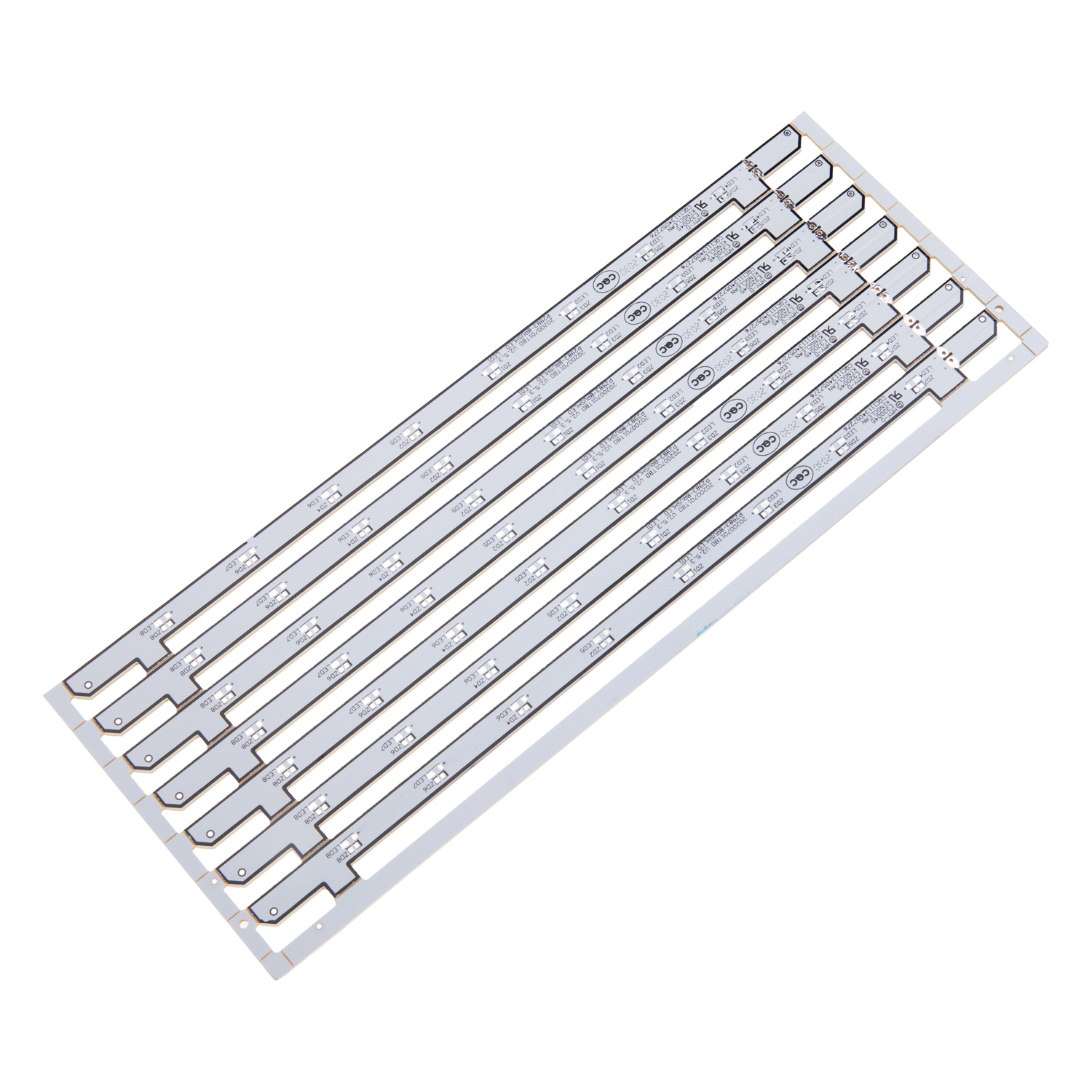

Metal Core Aluminum Base PCB: Metal core PCBs (MCPCBs) use a base layer of metal, typically aluminum, to offer enhanced heat dissipation. This type of PCB is ideal for high-power and high-temperature applications such as LED lighting.

2. Thermal Management

FR4 PCB: FR4 offers decent insulation but poor heat dissipation. It works well in low-power applications where heat buildup is minimal.

Metal Core Aluminum Base PCB: The aluminum base of metal core PCBs effectively dissipates heat away from heat-sensitive components, which is crucial in applications where temperature control is critical. At Hongmy Circuits, we design metal core PCBs with superior thermal management to ensure the longevity and reliability of your devices.

3. Performance in High-Power Applications

FR4 PCB: While suitable for many general electronic devices, FR4 PCBs struggle in high-power situations due to their inability to handle heat efficiently.

Metal Core Aluminum Base PCB: Designed specifically for high-power applications, metal core PCBs are used in industries where heat needs to be quickly dissipated, such as automotive, aerospace, and industrial lighting. Hongmy Circuits specializes in creating metal core PCBs that excel in these demanding environments.

4. Durability and Strength

FR4 PCB: While FR4 is strong and rigid, it is not suited for environments with extreme temperatures or high mechanical stress.

Metal Core Aluminum Base PCB: The aluminum base offers not only thermal advantages but also mechanical strength, making metal core PCBs more durable in harsh conditions.

5. Cost Considerations

FR4 PCB: Due to their simpler materials and manufacturing process, FR4 PCBs tend to be more cost-effective, especially for mass production in consumer electronics.

Metal Core Aluminum Base PCB: The inclusion of a metal layer increases manufacturing costs, but the added benefits of heat dissipation and durability justify the expense for specific high-performance applications. Hongmy Circuits ensures competitive pricing without compromising on quality.

6. Applications

FR4 PCB: Suitable for consumer electronics, telecommunications, and general electrical appliances where heat management isn’t a primary concern.

Metal Core Aluminum Base PCB: Best for LED lighting, power supplies, automotive electronics, and other high-power systems that require efficient heat dissipation. Hongmy’s metal core PCBs are crafted for optimal performance in these sectors.

Conclusion: Choosing the Right PCB for Your Needs

In summary, the main difference between FR4 PCBs and metal core aluminum base PCBs lies in their material composition and heat management capabilities. FR4 PCBs are great for general electronics that don't require heavy heat dissipation, while metal core aluminum base PCBs are better suited for high-power applications where thermal management is crucial.

At Hongmy Circuits, we offer top-quality metal core aluminum base PCBs and FR4 PCBs, customized to meet your project’s specific needs. Whether you require high durability, heat resistance, or cost-effective solutions, we provide expert guidance to help you make the best choice for your application.

Visit our website Hongmy Circuits to explore our PCB products and services!