In the dynamic world of electronics manufacturing, innovation and precision are paramount. Among the advancements propelling the industry forward, 8-layer High-Density Interconnect (HDI) Printed Circuit Boards (PCBs) stand out as a cornerstone for cutting-edge electronic designs. This guide delves into the significance of 8-layer hdi pcb boards for oems, highlighting their benefits, applications, and the process of working with an OEM for custom PCB solutions.

What Are 8-Layer HDI PCB Boards?

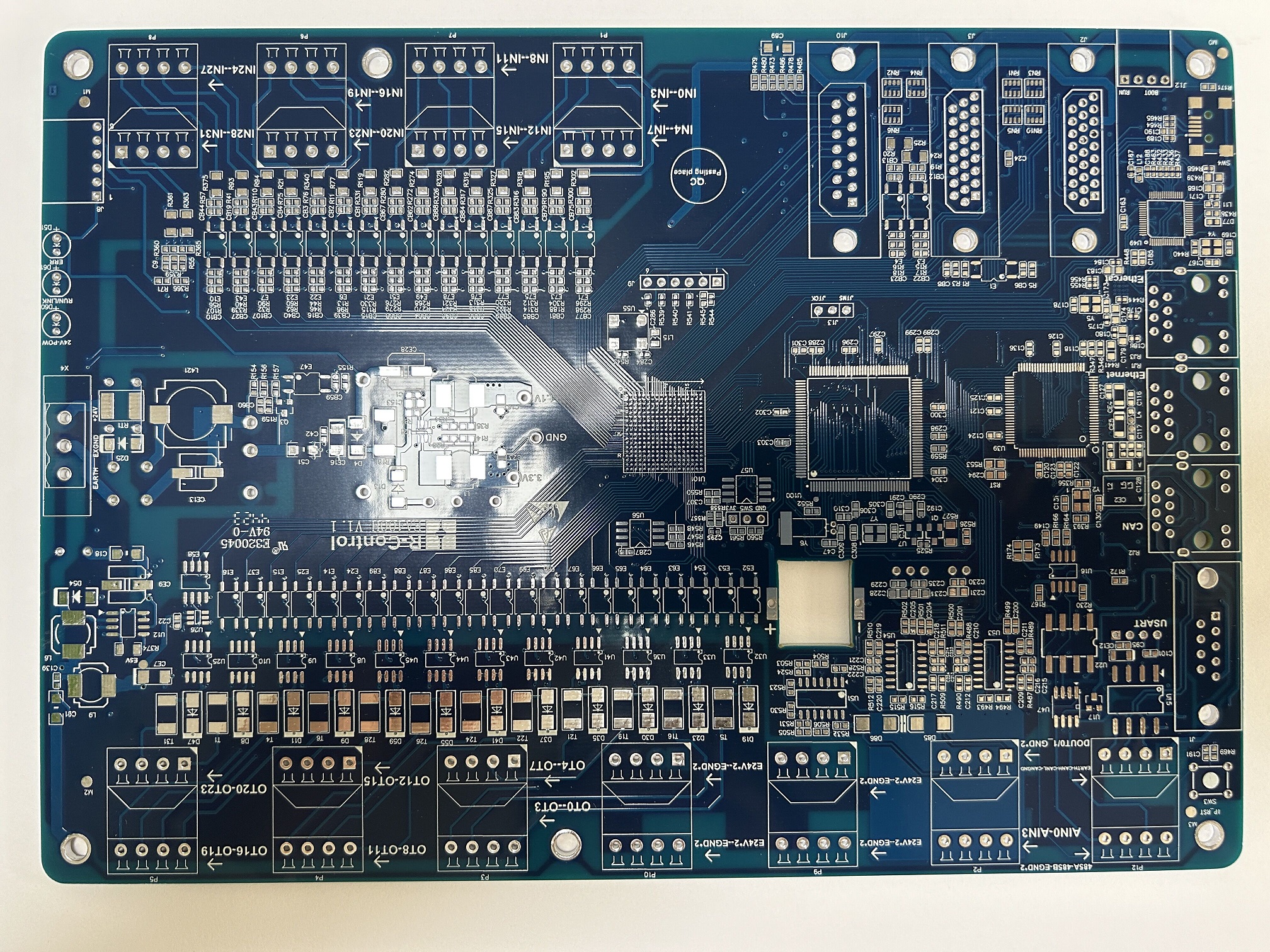

8-layer HDI PCBs are advanced circuit boards characterized by their multiple layers and high-density interconnections. They are designed to support complex circuitry in a compact space, offering enhanced performance and reliability. HDI technology utilizes finer lines, smaller vias, and higher connection pad density compared to traditional PCBs, making it ideal for sophisticated electronic devices.

Benefits of 8-Layer HDI PCB Boards

1. High Performance and Reliability:

8-layer HDI PCBs provide superior electrical performance due to their multiple layers and high-density connections. This results in faster signal transmission, reduced signal loss, and improved overall reliability.

2. Compact and Lightweight Designs:

The ability to integrate more circuitry into a smaller area allows for compact and lightweight electronic devices. This is particularly beneficial for modern applications where space is at a premium.

3. Enhanced Thermal Management:

HDI PCBs are designed to effectively dissipate heat, ensuring optimal performance and longevity of electronic components. This is crucial for devices that operate at high speeds and generate significant heat.

4. Increased Functionality:

With more layers and higher interconnection density, 8-layer HDI PCBs can support more complex functions and features, enabling the development of advanced electronic products.

Applications of 8-Layer HDI PCB Boards

1. Consumer Electronics:

From smartphones and tablets to wearables and gaming consoles, 8-layer HDI PCBs are integral to the compact and powerful devices that dominate the consumer electronics market.

2. Medical Devices:

In medical technology, HDI PCBs are used in diagnostic equipment, patient monitoring systems, and wearable health devices, where reliability and precision are critical.

3. Aerospace and Defense:

The aerospace and defense industries rely on HDI PCBs for avionics, communication systems, and other high-performance applications that demand robust and compact solutions.

4. Automotive Electronics:

Modern vehicles incorporate HDI PCBs in their infotainment systems, advanced driver-assistance systems (ADAS), and engine control units, enhancing safety, functionality, and user experience.

5. Industrial Automation:

HDI PCBs are used in industrial control systems, robotics, and automation equipment, where they provide the necessary performance and durability for demanding environments.

Working with an OEM for Custom 8-Layer HDI PCBs

Partnering with an Original Equipment Manufacturer (OEM) for custom 8-layer HDI PCBs can streamline the production process and ensure high-quality results. Here’s how to approach this collaboration:

1. Define Your Requirements:

Clearly outline your product’s specifications, including size constraints, performance criteria, and any specific features needed. This helps the OEM understand your needs and develop a suitable design.

2. Choose the Right OEM:

Select an OEM with a proven track record in manufacturing HDI PCBs. Look for experience, certifications, and customer reviews to gauge their reliability and expertise.

3. Collaborate on Design:

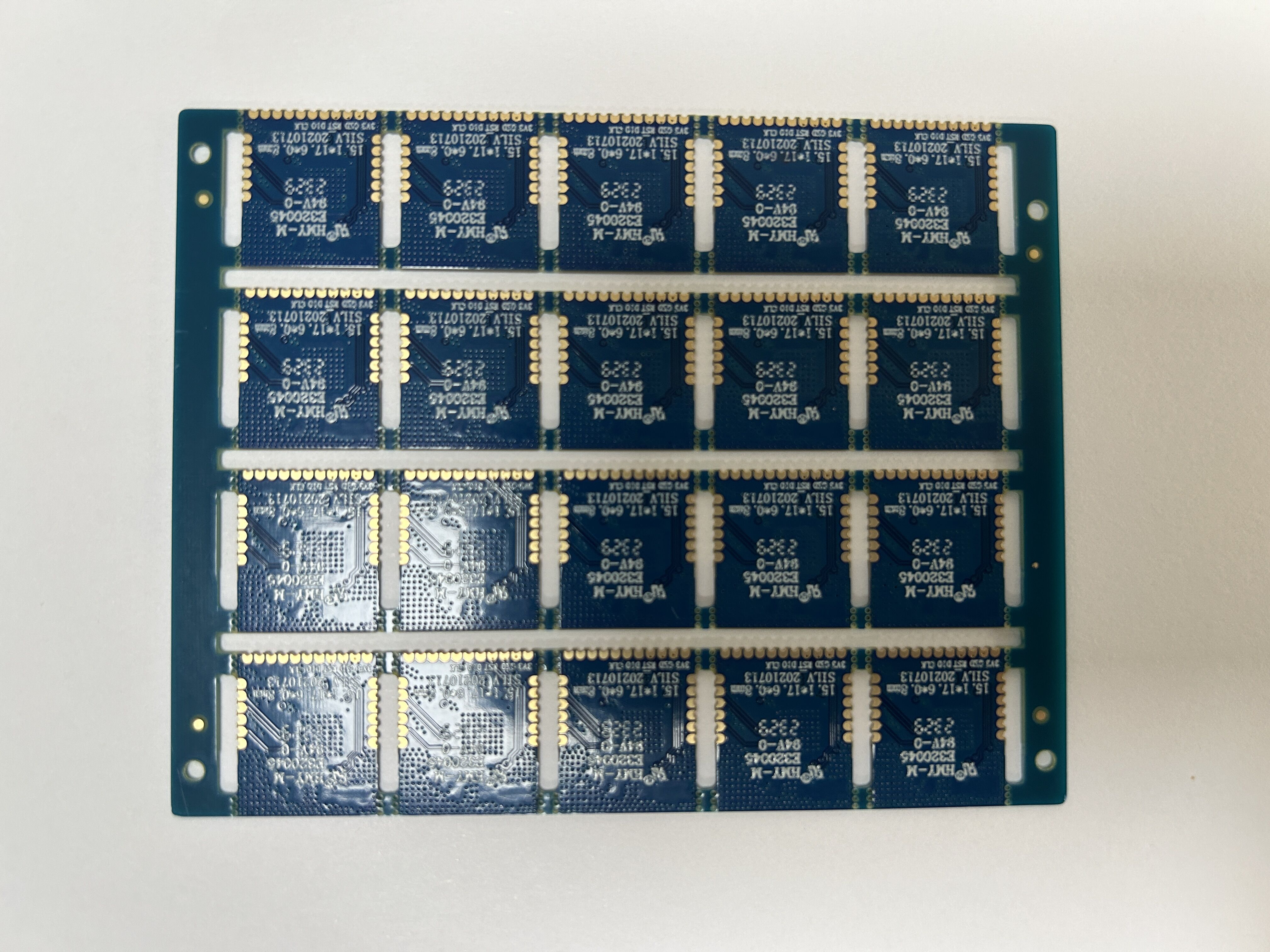

Work closely with the OEM’s engineering team to finalize the design. This may involve several iterations and prototypes to ensure the PCB meets your exact requirements.

4. Ensure Quality Control:

Ensure that the OEM follows stringent quality control measures throughout the manufacturing process. This includes testing for electrical performance, thermal management, and durability.

5. Plan for Scalability:

Discuss production volumes and timelines with the OEM to ensure they can scale up manufacturing as needed. This is crucial for meeting market demand and maintaining supply chain efficiency.

Conclusion

8-layer HDI PCB boards are revolutionizing the electronics industry by enabling high-performance, compact, and reliable designs. For OEMs, understanding the benefits and applications of these advanced PCBs is key to staying competitive and innovative. By partnering with a reputable OEM and following best practices in the design and manufacturing process, you can unlock the full potential of 8-layer HDI PCBs for your next groundbreaking electronic product.